5 Aerodynamics

Recurring Terminology

| Symbol | Definition |

|---|---|

| \(a\) | slope of lift curve, \(dC_L/d\alpha\) |

| \(\mathrm{ac}\) | aerodynamic center, location along the chord where pitching moments about this center do not change with angle of attack (25% \(\mathrm{MAC}\) for airfoils in subsonic flow, 50% \(\mathrm{MAC}\) for airfoils in supersonic flow) |

| \(\mathrm{AOA}\) | angle of attack |

| \(\mathrm{AR}\) | aspect ratio \(= [\text{wing span}]^2 / [\text{reference wing area}] = b^2/S\) |

| \(B\) | wing span |

| \(b_t\) | horizontal tail span |

| \(C\) | coefficient, a non-dimensional representation of an aerodynamic property |

| \(c\) | wing chord length Camber maximum curvature of an airfoil, measured at maximum distance between chord line and amber line, expressed in % of \(\mathrm{MAC}\). Camber line theoretical line extending from an airfoil’s leading edge to the trailing edge, located halfway between the upper and lower surfaces. |

| \(C_D\) | drag coefficient |

| \(C_{D_i}\) | induced drag coefficient |

| \(C_{D_0}\text{, }C_{D_{\mathrm{PE}}}\) | parasitic drag coefficient |

| \(c_f\) | friction coefficient |

| Chord | straight-line distance from an airfoil’s leading edge to its trailing edge |

| \(C_L\) | lift coefficient |

| \(C_p\) | pressure coefficient = \(\Delta p/q\) |

| \(e\) | Oswald efficiency factor |

| \(l\) | distance traveled by flow, or characteristic length of surface |

| \(M\) | Mach number |

| \(\mathrm{MAC}\) | mean aerodynamic chord, chord length of location on wing where total aerodynamic forces can be concentrated. |

| \(\mathrm{MGC}\) | mean geometric chord, the average chord length, derived only from a plan form view of a wing (similar to \(\mathrm{MAC}\) if wing has no twist and constant cross section & thickness-to-chord ratio). |

| \(P\) | pressure |

| \(P_\text{req'd}\) | power required |

| \(q\) | dynamic pressure = \(\frac{1}{2} \rho_a V_T^2 = \frac{1}{2} \rho_0 V_T^2\) |

| \(R\) | gas constant |

| \(\mathrm{Rn},\mathrm{Re}\) | Reynolds number |

| \(S\) | reference wing area, includes extension of wing to fuselage centerline. |

| \(S_t\) | horizontal tail surface area |

| \(S_W\) | wetted area of surface |

| \(T\) | temperature |

| \(V\) | true velocity |

| \(V_e\) | equivalent velocity |

| \(\alpha\) | angle of attack |

| \(\alpha_i\) | induced angle of attack |

| \(\delta\) | depth of boundary layer, or surface wedge angle |

| \(\mu\) | viscosity, or wave angle |

| \(\nu\) | flow turning angle |

| \(\theta\) | shock wave angle |

| \(\rho\) | density |

- Perfect Fluid

- incompressible, inelastic, and non-viscous

- used in flow outside of boundary layers at \(M\) < .7

- Incompressible, inelastic, viscous

- used for boundary layer studies at \(M\) < .7

- Compressible, non-viscous, elastic fluid

- used outside boundary layers up to \(M\) = 5

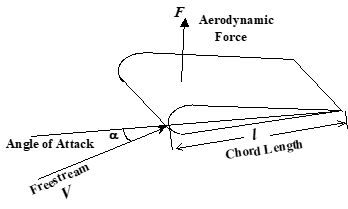

5.1 Dimensional Analysis Interpretations

(ref 5.2)

Aerodynamic force = \(F\)

- \(F = f \left( \rho \text{, } \mu, T \text{, } V \text{, shape, orientation, size, roughness, gravity} \right)\)

- For aircraft ignore \(R\), \(K\) & hypersonic effects

- Initially assume similar body orientations, shapes & roughness.

- Dimensional Analysis reveals four non-dimensional (\(\pi\)) parameters:

- Force Coefficient \(\pi_1 = \frac{F}{\rho V^2 l^2}\)

- Reynolds Number \(\pi_2 = \frac{\rho V l}{\mu}\)

- Mach Number \(\pi_3 = \frac{V}{a}\)

- Froude Number \(\pi_4 = \frac{V}{\sqrt{lg}}\)

A closer look at the force coefficient:

\[C_F = \frac{F}{\rho V^2 l^2} => \frac{F}{\frac{1}{2} \rho V^2 S} \]

where \(\frac{1}{2} \rho_a V_T^2 = \frac{1}{2} \rho_0 V_e^2 = \text{dynamic pressure}\text{, }q\)

Dimensions of reference wing area, \(S\) are the same

A feel for \(q\)

- Kinetic energy of a moving object = \(\frac{1}{2} m V_T^2\)

- Block of moving air kinetic energy = \(\frac{1}{2} \rho \text{ (volume) } V_T^2\)

- Dividing through by volume yields \(\mathrm{KE}\) per volume of moving air = \(\frac{1}{2} \rho V_T^2\)

- “Dynamic pressure” or “\(q\)” = potential for converting each cubic foot of the airflow’s kinetic energy into frontal stagnation pressure

- Feel \(q\) by extending your hand out the window of a moving car

A feel for coefficients

- \(C_F = (F/S)/q\) = the ratio between the total force pressure and the flow’s dynamic pressure

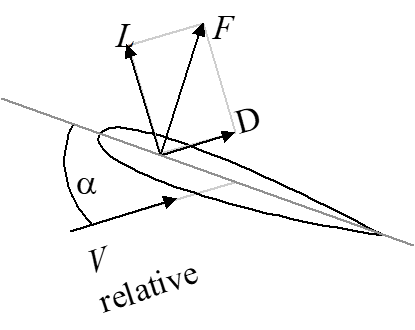

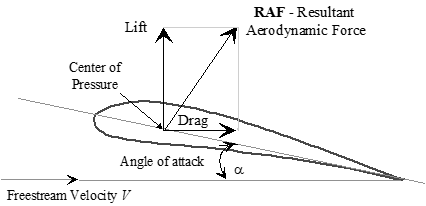

- Lift is the component of the total force perpendicular to the free stream flow

- Drag is the component along the flow

- Break total into lift and drag coefficients:

- \(C_L = (L/S)/q\)

- \(C_D = (D/S)/q\)

- Increasing dynamic pressure generates a larger total force, lift and drag

- Froude number is not significant in aerodynamic phenomena

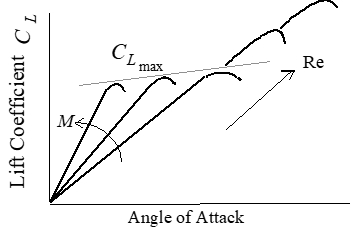

- Recall that forces are also a function of angle of attack, shape & surface roughness, therefore

\[C_L,C_D = f \left[ M \text{, } \mathrm{Re} \text{, } \alpha \right] \text{ for a given shape, roughness} \]

Note in the figure above the Reynolds effects are exaggerated

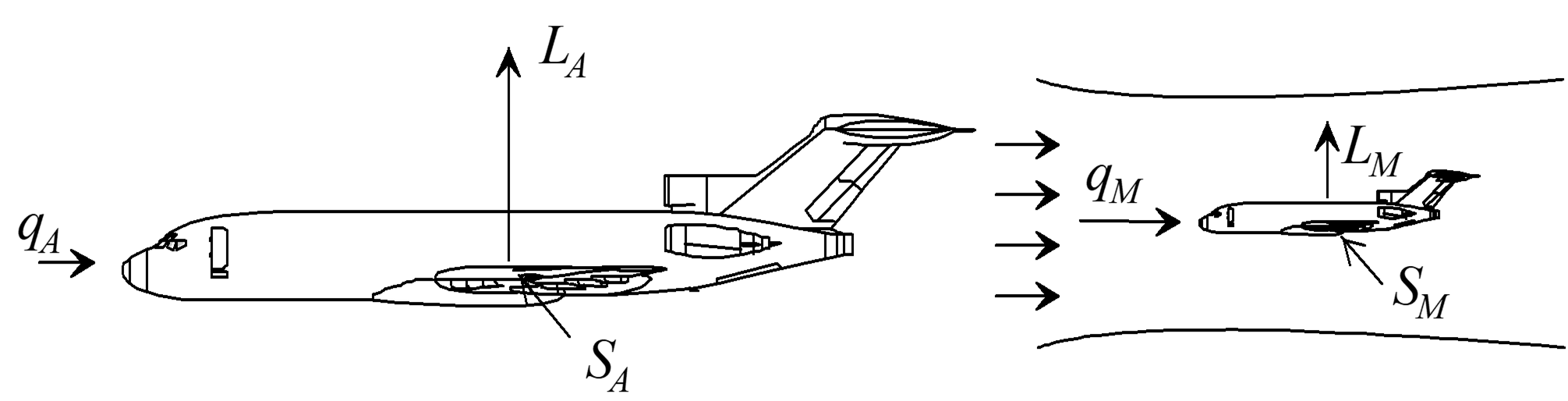

To compare test day and standard day aircraft or to match wind tunnel \(C_F\) data to actual aircraft; the shape, roughness, \(M\), \(\mathrm{Rn}\) and \(\alpha\) must be equal for both aircraft

\[\frac{L_A}{q_A S_A} = C_L = \frac{L_M}{q_M S_M} \]

5.2 General Aerodynamic Relations

(refs 5.1, 5.2, 5.10)

Lift & Drag forces can be described using two approaches:

- Change in momentum of airstream, \(F=d[mv]/dt\)

- “Bernoulli” approach which requires the continuity and conservation of energy equations

Continuity Equation

Fluid Mass in = Fluid Mass out

\[\rho_1 V_1 A_1 = \rho_2 V_2 A_2\]

For subsonic (incompressible) flow \(\rho_1 = \rho_2\)

\[V_1 A_1 = V_2 A_2\]

Conservation of Energy (Bernoulli) Equation:

Potential + Kinetic + Pressure = constant (changes in Potential energy are negligible)

Energy per unit volume is pressure then Dynamic Pressure + Static Pressure = Total Pressure

\[\frac{1}{2}\rho V^2 + p_s = \text{constant} \] \[\frac{1}{2}\rho V^2 + p_s = p_t \]

- This classic approach only applies in the “potential flow” region and not in the boundary layer where energy losses occur

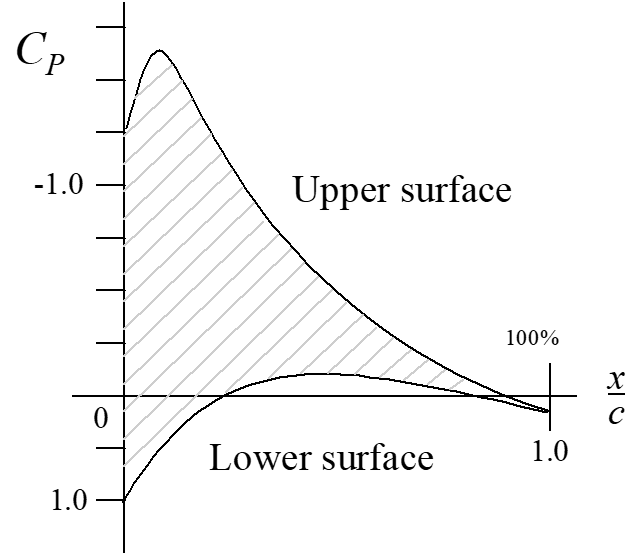

- Pressures around a surface can be calculated or measured from tests and converted into pressure coefficients,

\[c_p = \left( p_{\mathrm{local}} - p_{\mathrm{ambient}} \right) / \text{dynamic pressure} = \Delta p/q \]

- \(c_p\) values can be mapped out for all surfaces

- Summation of all pressures perpendicular to surface yield the pitching moments and the “Resultant Aerodynamic Force” which is broken into lift and drag components

- Lift & drag forces are referred to the aerodynamic center (\(\mathrm{ac}\)) where the pitching moment is constant for reasonable angles of attack.

- Pitching moments increase with airfoil camber, are zero if symmetric.

- Aerodynamic center is located at 25% \(\mathrm{MAC}\) for fully subsonic flow and at 50% \(\mathrm{MAC}\) for fully supersonic flow.

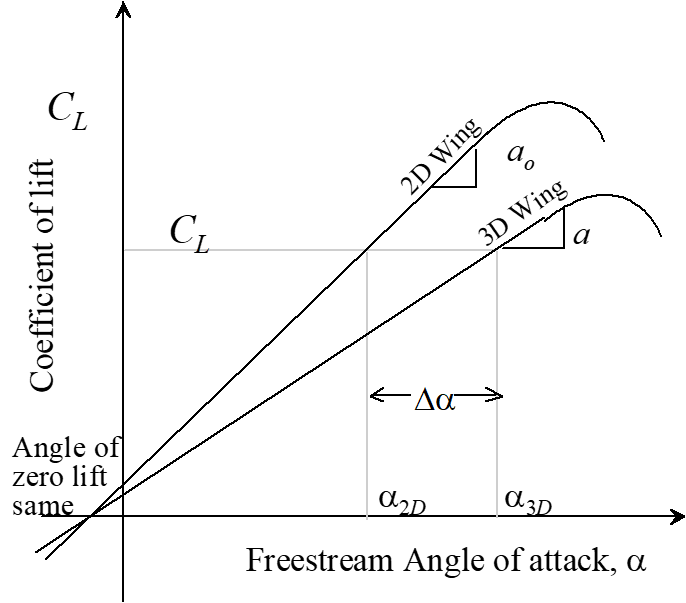

5.3 Wing Design Effects on Lift Curve Slope

(refs 5.1, 5.2, 5.10)

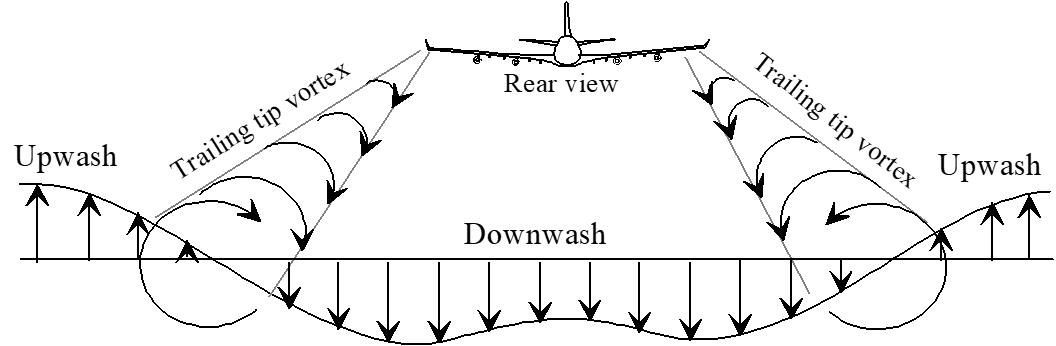

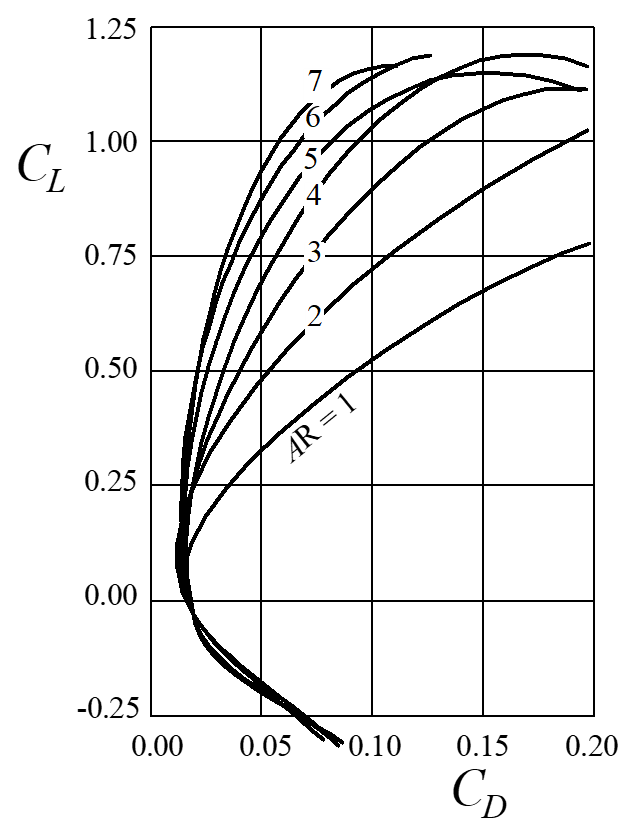

Aspect Ratio Effect

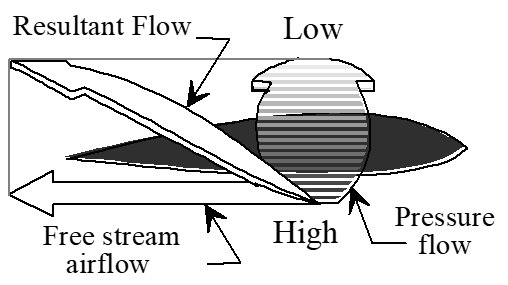

- Pressure differential at wingtip causes tip vortex

- Vortex creates flow field that reduces \(\mathrm{AOA}\) across wingspan

- Local \(\mathrm{AOA}\) reductions decrease average lift curve slope

2D wing = wind tunnel airfoil extending to walls (infinite aspect ratio).

\(a_0 = \text{Lift curve slope for an infinite wing}\)

\(a = \text{Lift curve slope for a finite wing}\)

- Above relationship estimated as \(\alpha = \frac{dC_L}{d \alpha} = \frac{a_0}{1+\frac{57.3 a_0}{\pi \mathrm{AR}}}\)

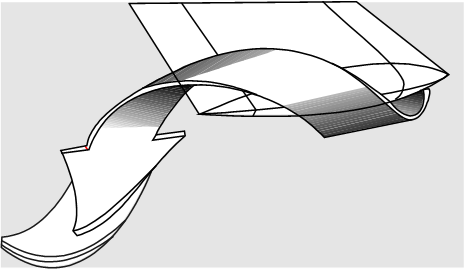

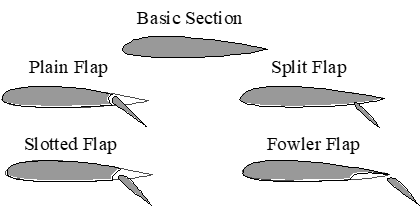

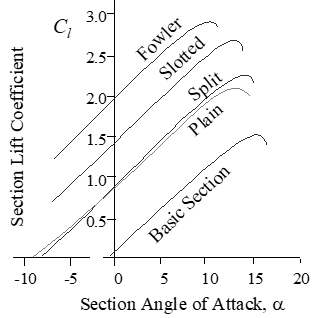

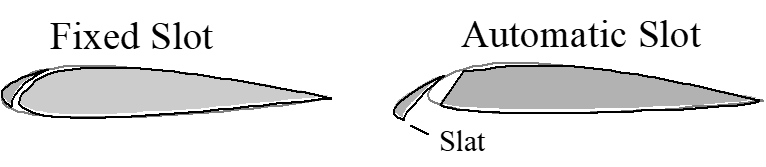

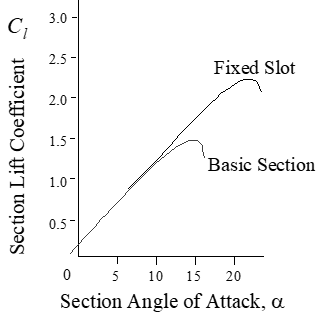

Trailing Edge Flap Effects

Leading Edge Flap Effects

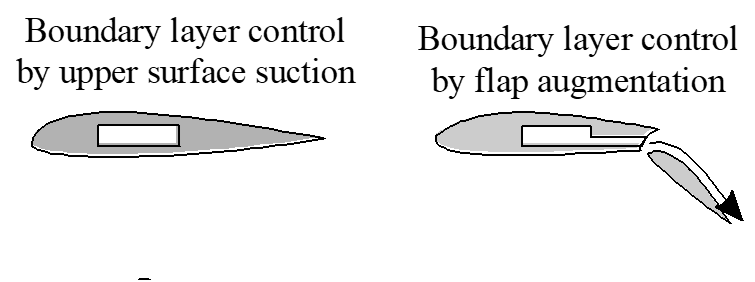

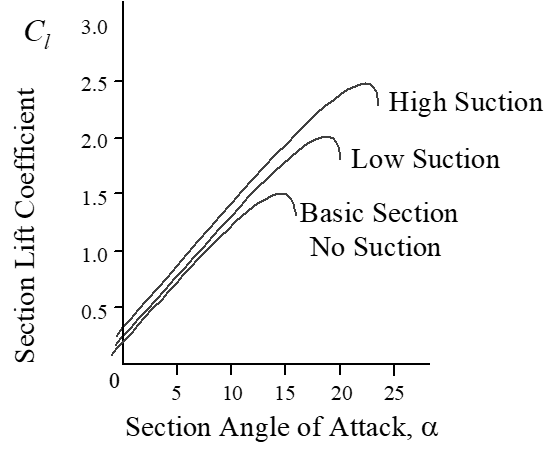

Boundary Layer Control Effects

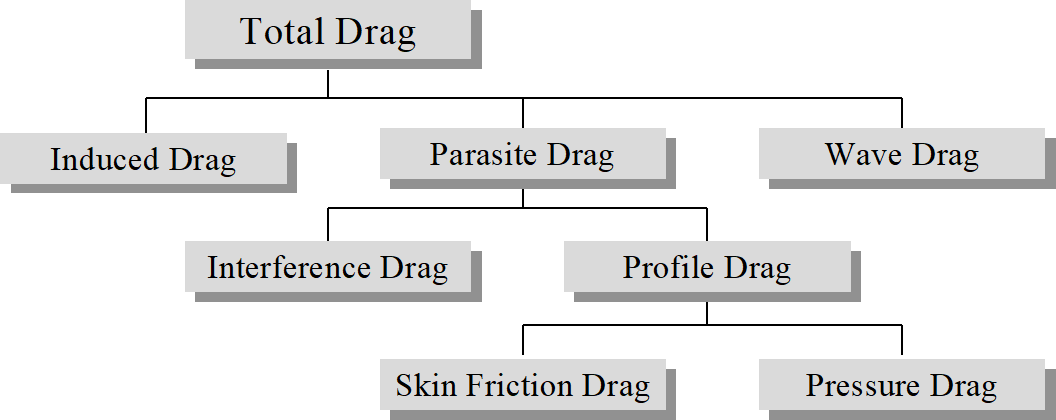

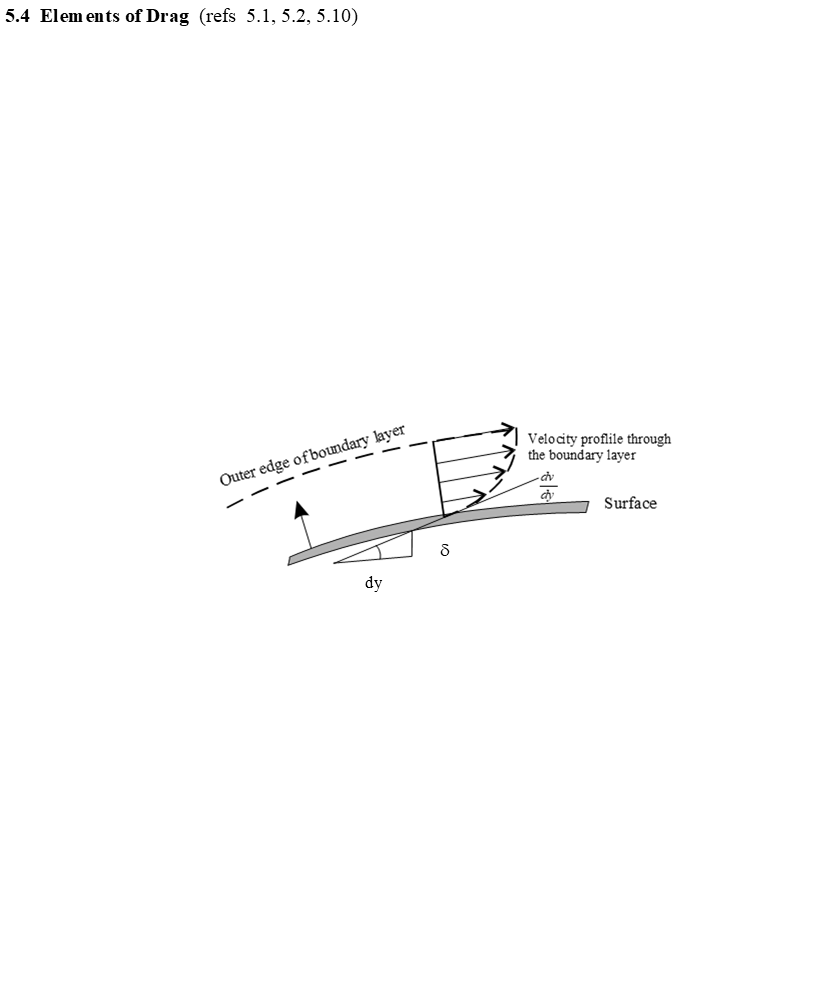

5.4 Elements of Drag

(refs 5.1, 5.2, 5.10)

- Skin friction shear stress is a function of velocity profile at surface

Shear stress \(\tau_w = \mu \left( \frac{dv}{dy} \right)_{y=0}\)

- Viscosity \(\mu\) increases with temperature (ref 5.9)

Sutherland law: \(\mu = \mu_0 \frac{\left( \frac{T}{T_0} \right)^{1.5} \left( T_0 + S \right)}{\left( T + S \right)}\)

Power law: \(\mu = \mu_0 \left( \frac{T}{T_0} \right)^n\)

Where \(T_0 = 273.15 \text{K} = 518.67 \text{R}\)

For air: \(S = 110.4 \text{K} = 199 \text{R} \text{; n=0.67}\)

For air at \(273\) K : \(\mu_0 = 1.717 \times 10^{-5} \left[\text{kg/m s}\right] = 3.59 \times 10^{-7} \left[\text{slug/ft s}\right]\)

Inserting air values (\(T_K=\)Kelvin and \(T_R=\)Rankin) into Sutherland law gives

\[\mu = 1.458 \times 10^{-6} \frac{T_K^{1.5}}{T_K+110.4} \left[\frac{\text{kg}}{\text{s m}}\right] = 2.2 \times 10^{-8} \frac{T_R^{1.5}}{T_R+199} \left[\frac{\text{slug}}{\text{s ft}}\right]\]

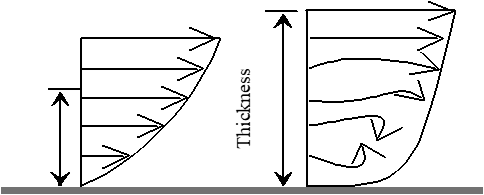

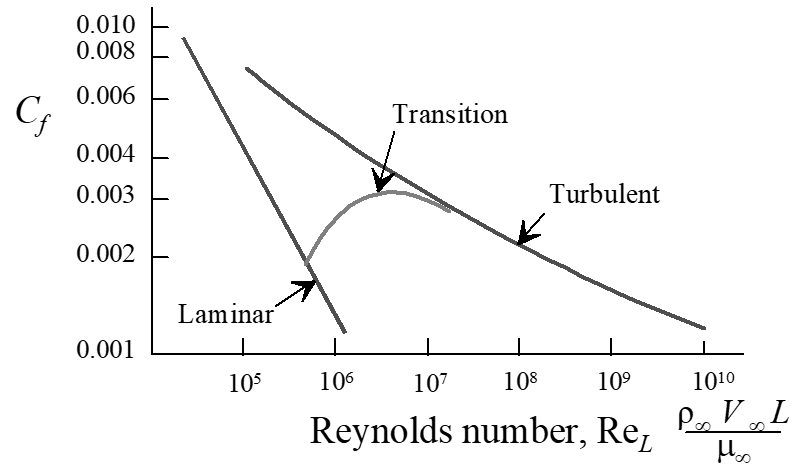

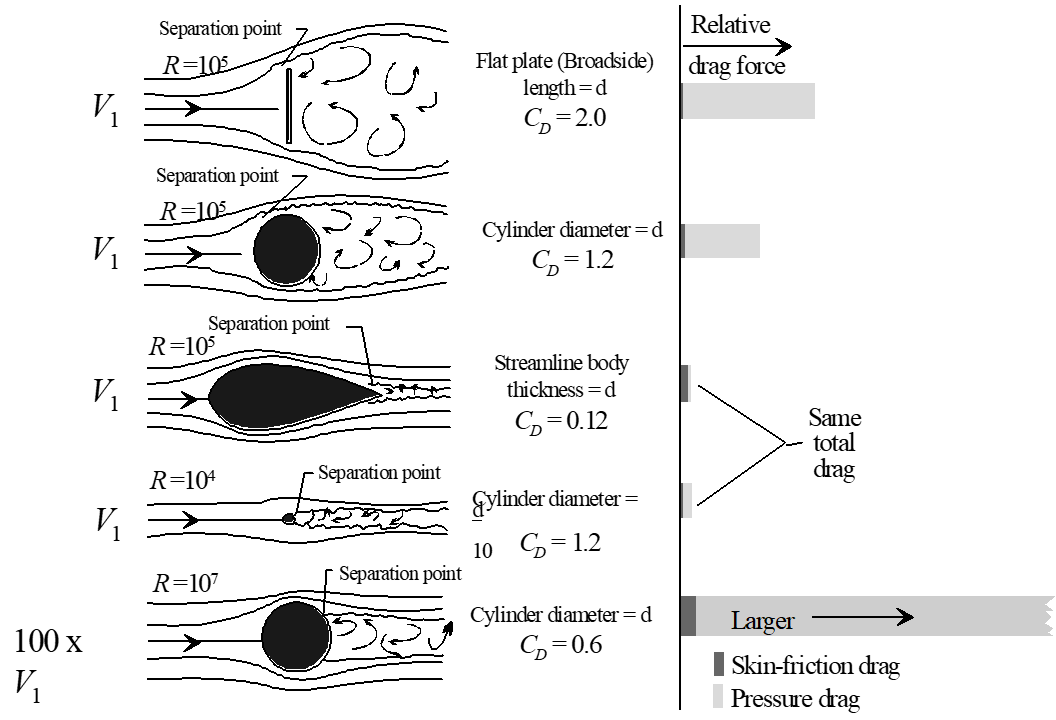

5.4.1 Reynolds Number Effects

(ref 5.10)

- Laminar boundary layers have more gradual change in velocity near surface than turbulent boundary layers.

- High Reynolds numbers help propagate turbulent flow.

Shearing stress: \(\tau_w = \mu \left(\frac{dv}{dy}\right)_{y=0}\)

Skin friction coefficient: \(C_f = \frac{\tau_w}{\frac{1}{2}\rho_{\infty} V_{\infty}^2} = \frac{\tau_w}{q_{\infty}}\)

Laminar boundary layer: \(\text{Total } C_f = \frac{1.328}{\left(\mathrm{Re}_L \right)^{1/2}}\)

Turbulent boundary layer: \(\text{Total } C_f = \frac{0.455}{\left(\log(\mathrm{Re}_L)\right)^{2.58}} \approx \frac{0.074}{\left(\mathrm{Re}_L\right)^{1/5}}\)

\(\mathrm{Re}_L\) based on total length of flat plate

- Depth of boundary layer \((\delta)\) depends on local Reynolds number \((\mathrm{Re}_x)\) and whether the flow is turbulent or laminar.

\[\mathrm{Re}_x = \frac{\rho_{\infty} V_{\infty} x}{\mu_{\infty}} \equiv \frac{\text{Inertia Forces}}{\text{Viscous Forces}} \]

\(x =\) distance traveled to point in question

\[\delta_{\mathrm{lam}} = \frac{5.2x}{\sqrt{\mathrm{Re}_x}} \]

\[\delta_{\mathrm{turb}} = \frac{0.37x}{\mathrm{Re}_x^{0.2}} \]

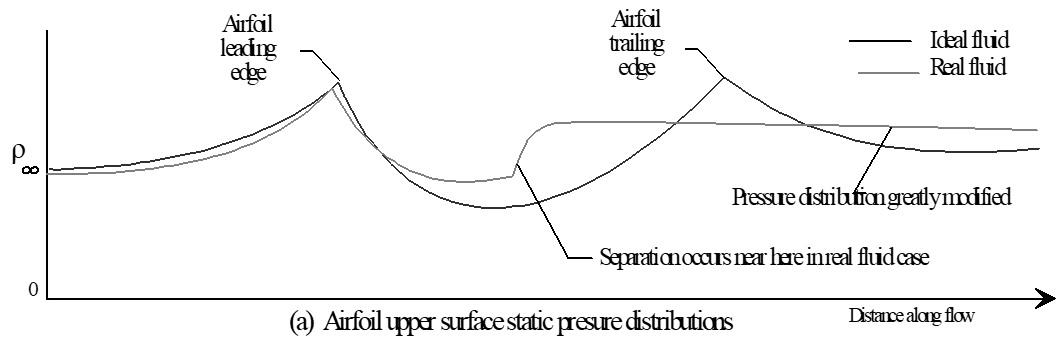

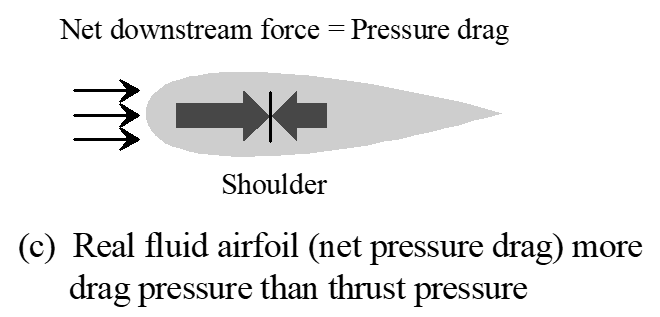

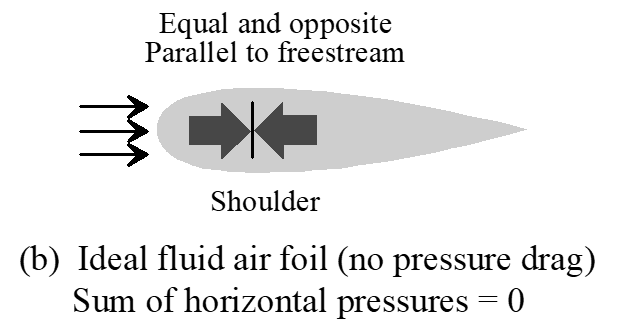

5.4.2 Pressure Drag

- Ideal frictionless flow has no losses and leads to zero pressure drag

- Real fluids have friction and energy losses along surface

- Energy losses negate total pressure recovery, lead to decreasing total pressure along surface

- Imbalance of pressures on surfaces causes pressure drag

- Profile streamlining reduces pressure drag

5.4.3 Interference Drag

- Occurs with multiple surfaces approximately parallel to flow

- Caused by flow’s interference with itself or by excessive adverse pressure gradient due to rapidly decreasing vehicle cross section

- Most severe with surfaces at acute angles to each other

- Effects often reduced by fillets around contracting surfaces

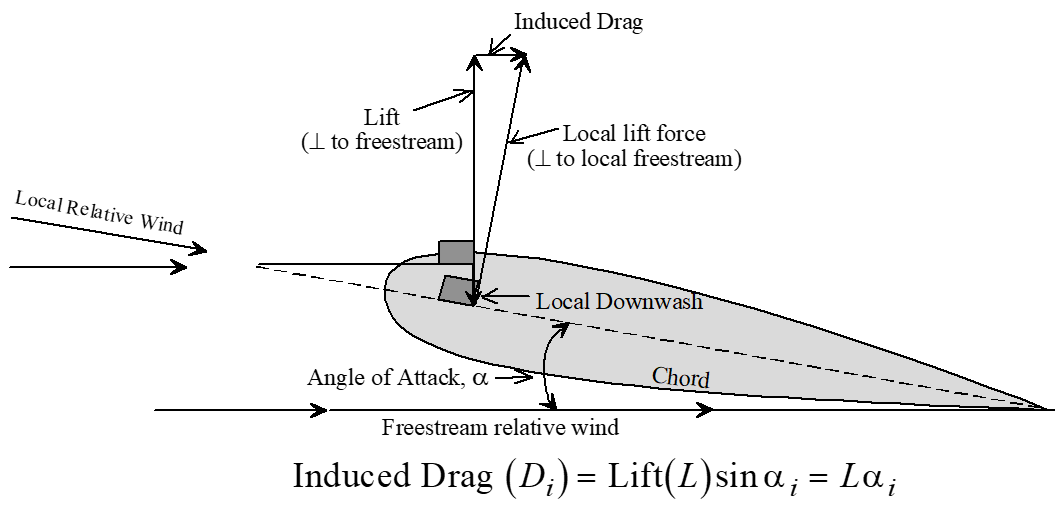

5.4.4 Induced Drag

- Wingtip vortex reduces local \(\mathrm{AOA}\) at each station along wing

- Local lift vector is perpendicular to local \(\mathrm{AOA}\)

- Local lift vector is therefore tilted back relative to freestream lift

- Induced drag defined as rearward component of local lift vector

Induced Drag \[\left(D_i\right)=L\left(\alpha_i\right)\]

For elliptical lift distributions \(\alpha_i = \frac{C_L}{\pi \mathrm{AR}}\)

\[\therefore D_i = L \left(\frac{C_L}{\pi \mathrm{AR}}\right) \text{ but } L=qSC_L \]

\[C_{D_i} = \frac{D_i}{qS} = \frac{C_L^2}{\pi \mathrm{AR}}\]

Oswald efficiency factor, \(e\), accounts for losses in excess of those predicted above (due to uneven downwash and changing interference drag effects).

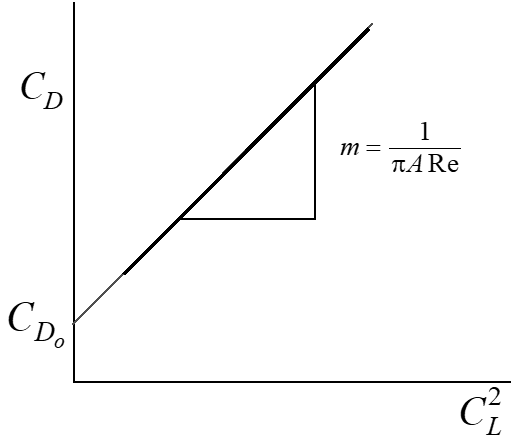

\[\therefore C_{D_i} = \frac{C_L^2}{\pi \mathrm{AR} e}\]

5.5 Aerodynamic Compressibility Relations

(ref 5.8)

Prandtl/Glauert Approximation

Approximates Mach effects on aerodynamics below critical Mach

\[C_{P_{\mathrm{compressible}}} = \frac{1}{\sqrt{1-M^2}}C_{P_{\mathrm{incompressible}}} \]

Total vs Ambient Property Relations for Adiabatic Flow

\[\frac{T_T}{T} = 1 + \frac{\gamma -1}{2}M^2 \text{ Isentropic flow not required}\] \[\frac{P_T}{P} = \left[1 + \frac{\gamma - 1}{2}M^2 \right]^{\frac{\gamma}{\gamma-1}} \text{ Isentropic (shockless) flow required}\] \[\frac{\rho_T}{\rho} = \left[1 + \frac{\gamma - 1}{2} M^2 \right]^{\frac{1}{\gamma -1}} \text{ Isentropic flow required} \]

Normal Shock Relations

Assumes isentropic flow on each side of the shock Assumes flow across shock is adiabatic Property changes occur in a constant area (throat)

\[\frac{P_2}{P_1} = \frac{1 - \gamma + 2\gamma M_1^2}{1+\gamma} \] \[\frac{\rho_2}{\rho_1} = \left[\frac{2 + \left(\gamma - 1\right) M_1^2}{\left(\gamma+1\right) M_1^2} \right]^{-1} \] \[\frac{T_2}{T_1} = \left[\frac{1 - \gamma + 2\gamma M_1^2}{1 + \gamma} \right]\left[\frac{2 + \left(\gamma - 1\right) M_1^2}{\left(1 + \gamma\right) M_1^2} \right] \] \[M_2^2 = \frac{M_1^2 + \frac{2}{\gamma - 1}}{\frac{2\gamma}{\gamma-1} M_1^2-1} \]

Normal shock summary

\(P_{T_1} > P_{T_2}\)

\(P_{1} < P_{2}\)

\(\rho_{T_1} > \rho_{T_2}\)

\(\rho_{1} < \rho_{2}\)

\(T_{T_1} > T_{T_2}\)

\(T_{1} < T_{2}\)

\(M_1 > M_2\)

\(s_1 < s_2\)

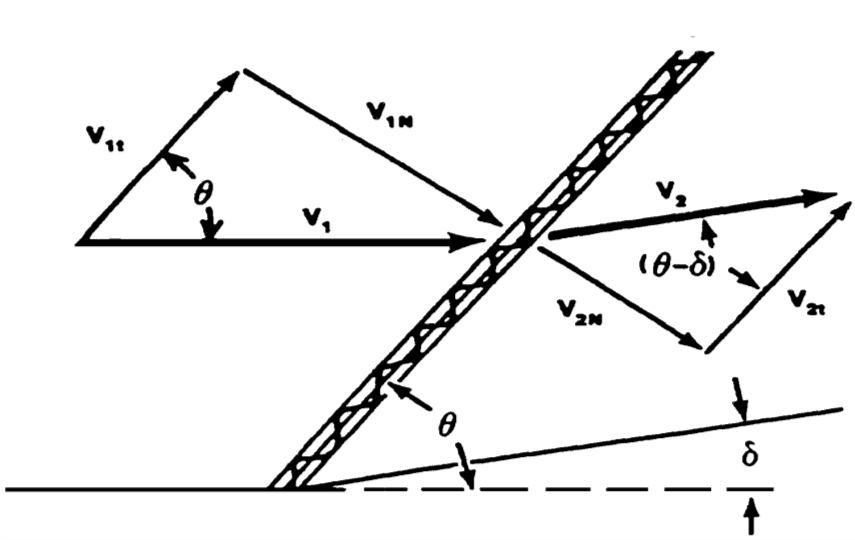

5.5.1 Oblique Shocks

Oblique Shock Description

\[\delta = \text{surface turning angle}\]

\[\theta = \text{shock wave angle}\]

\[\text{Subscript 1 denotes upstream conditions}\]

\[\text{Subscript 2 denotes downstream conditions}\]

Oblique Shock Relations

- Calculate \(P_2/P_1\), \(T_2/T_1\), and \(\rho_2/\rho_1\) across oblique shocks by using normal shock equations and substituting \(M_1 \sin\theta\) in place of \(M_1\)

- Calculate total pressure loss across oblique shock as

\[\frac{P_{T_2}}{P_{T_1}} = \left[\left[\frac{\gamma - 1}{\gamma + 1} + \frac{2}{{\left(\gamma + 1\right)M_1^2\sin^2\theta}}\right]^{\gamma} \left[\frac{2\gamma}{\gamma+1} M_1^2\sin^2\theta - \frac{\gamma - 1}{\gamma + 1} \right]\right]^{\frac{1}{1 - \gamma}} \]

- Calculate relation between Mach number and angles as

\[M_2^2\sin^2\left(\delta - \theta\right) = \frac{M_1^2 \sin^2\theta + \frac{2}{\gamma-1}}{\frac{2\gamma}{\gamma - 1} M_1^2\sin^2\theta - 1} \]

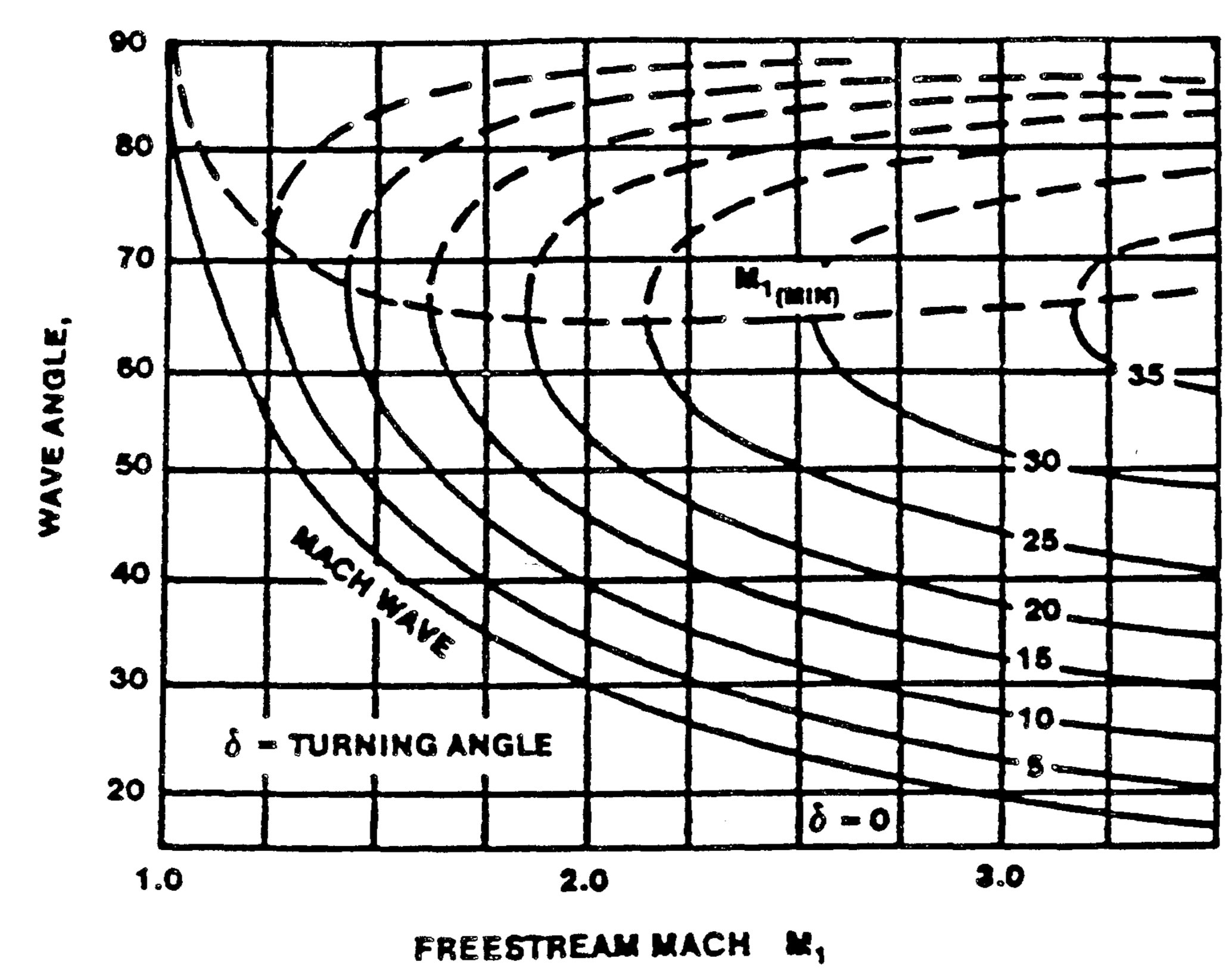

Oblique Shock Turning Angle as a Function of Wave Angle

- Two \(\theta\) solutions exist for every \(M_1\) & \(\delta\) combination

- These represent the strong and weak shock solutions

- Weak shocks normally occur in nature

- There is a minimum Mach number for each turning angle

- The wave angle of a weak shock decreases with increased Mach

- For a given Mach number, \(\theta\) approaches \(\mu\) as \(\delta\) decreases

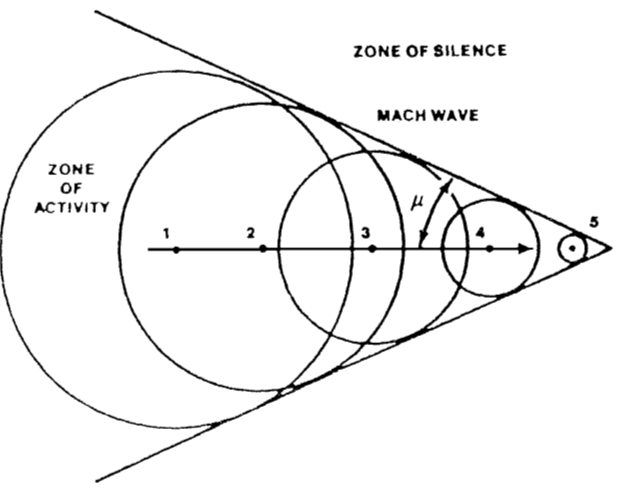

Mach Cone Angle

Minimum Wave Angle: \(\mu = \sin^{-1}\left(1/M\right)\)

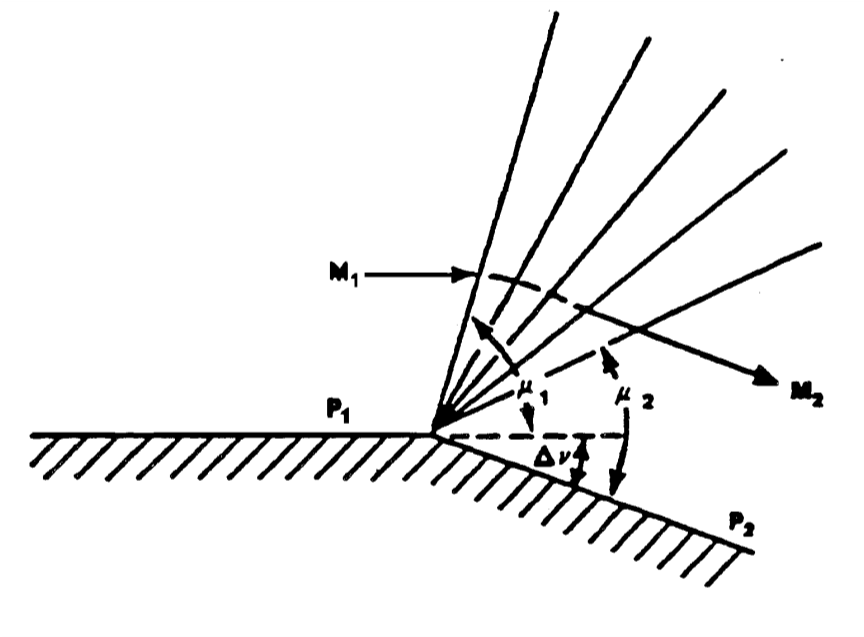

5.5.2 Supersonic Isentropic Expansion Relation

- The wave angle \(\mu\) determines where the lower pressure can be felt and thus where the flow can be accelerated

- As the flow accelerates, a new wave angle forms and the subsequent lower pressure further accelerates the flow

- Results in a series of Mach waves forming a “fan” until the flow turns and accelerates so that it is parallel to the new boundary

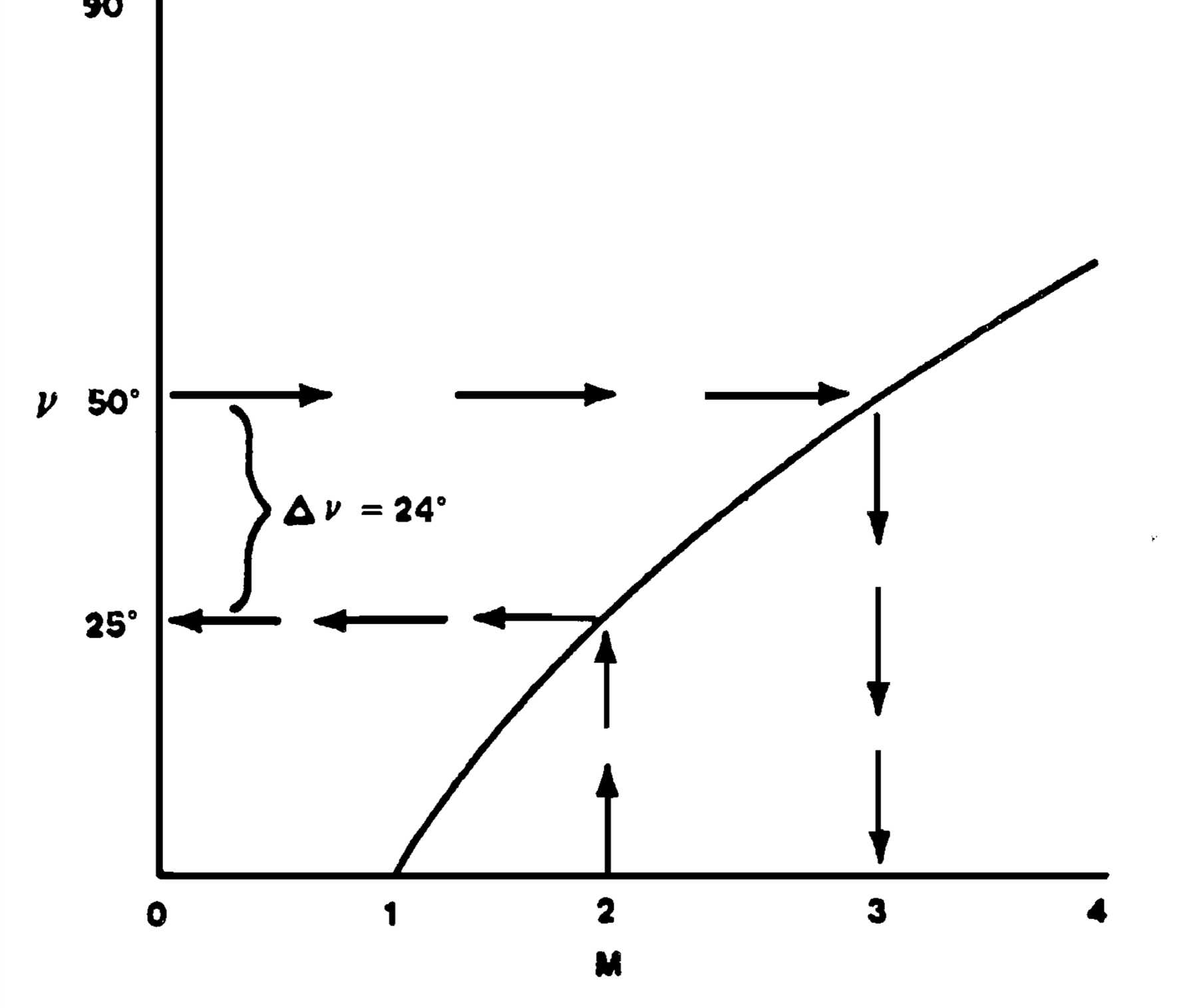

Prandtl-Meyer Function

Shows flow’s required turning angle (\(\nu\)) to accelerate from one Mach number to another

\[\nu_M = \sqrt{\frac{\gamma + 1}{\gamma - 1}} \left[\tan^{-1}\sqrt{\frac{\gamma - 1}{\gamma + 1} \left(M^2 - 1\right)} \right] - \tan^{-1}\sqrt{M^2-1} \]

- If upstream Mach \((M_1) = 1\), then \(\nu_1 = 0\), and equation directly relates downstream Mach (\(M_2\)) to surface turning angle (\(\Delta \nu\))

- If \(M_1 > 1\), determine \(M_2\) as follows:

- Calculate upstream ν1 from above equation

- Calculate \(\nu_2 = \nu_1 + \Delta \nu\)

- Reverse above equation to obtain corresponding \(M_2\)

- Above equation is tabulated in NACA TR 1135 and is plotted below

Example: Flow initially at \(M_1 = 2.0\) accelerates through an expansion corner of 24 deg. Exit Mach number is 3.0

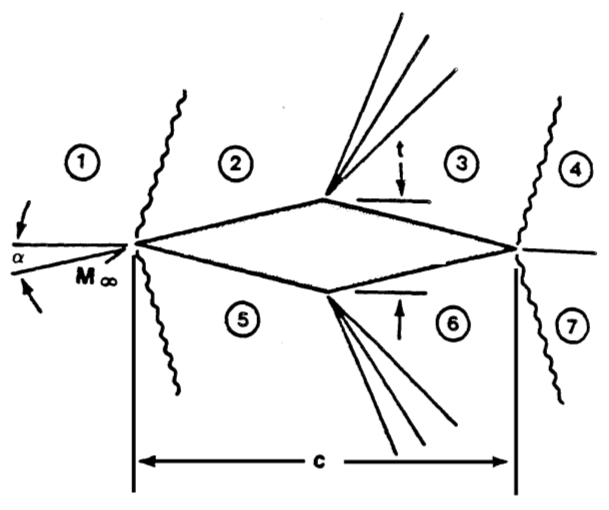

5.5.3 Two-Dimensional Supersonic Airfoil Approximations

- Determine surface static pressures by calculating changes through obliques shocks and expansion fans

- Ackert approximations for thin wings are based on

\[C_p = \frac{\Delta P}{q} \cong \pm\frac{2 \delta}{\sqrt{M^2 - 1}} \]

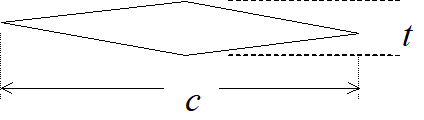

- Double wedge airfoil approximations

\[C_L \cong \frac{4 \alpha}{\sqrt{M^2 - 1} }\]

\[C_D \cong \frac{4 \alpha^2}{\sqrt{M^2 - 1}} + \frac{4}{\sqrt{M^2 - 1}}\left(\frac{t}{c}\right)^2\]

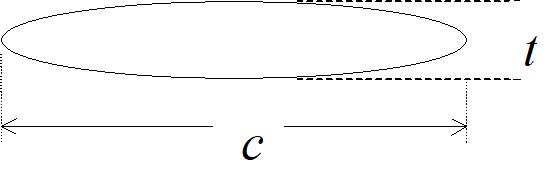

- Biconvex wing approximations

\[C_L \cong \frac{4 \alpha}{\sqrt{M^2 - 1} }\]

\[C_D \cong \frac{4 \alpha^2}{\sqrt{M^2 - 1}} + \frac{5.33}{\sqrt{M^2 - 1}}\left(\frac{t}{c}\right)^2\]

5.6 Drag Polars

(ref 5.2)

5.6.1 Drag Polar Construction and Terminology

\(C_L = \text{lift coefficient}\)

\(C_D = \text{drag coefficient}\)

\(C_{D_i} = \text{induced drag coefficient}\)

\(C_{D_0} = \text{parasitic drag coefficient}\)

\(\mathrm{AR} = \text{aspect ratio}\)

\(e = \text{Oswald efficiency factor}\)

\(l = \text{length flow has traveled}\)

\(S_{\mathrm{wet}} = \text{wetted area of surface}\)

\(S = \text{reference wing area}\)

Simple Drag Polar Equation Limitations

- No separated flow losses

- Symmetric Camber

- Applies at one Mach, Altitude, \(\mathrm{cg}\)

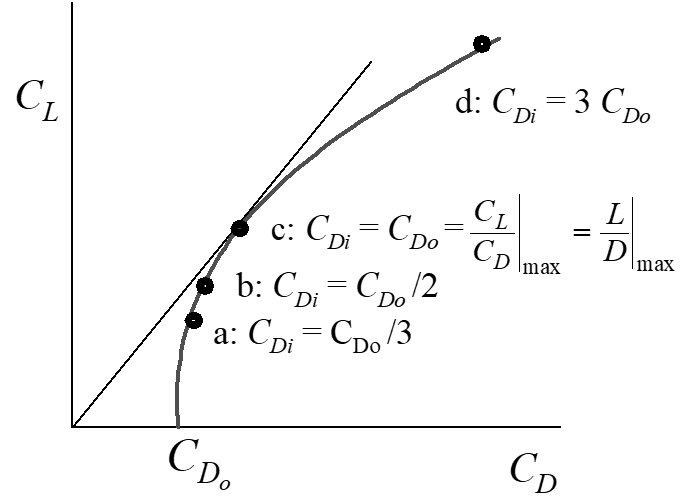

\[C_D = C_{D_0} + \frac{C_L^2}{\pi \mathrm{AR} e} = C_{D_0} + C_{D_i}\]

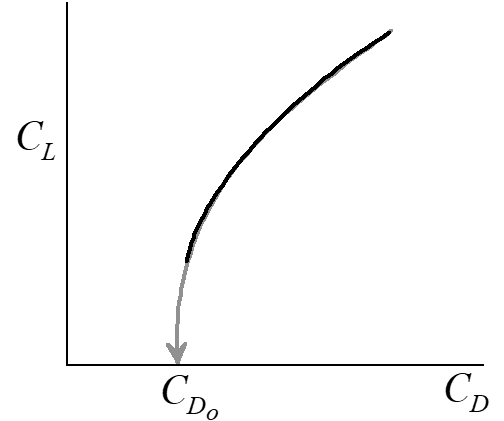

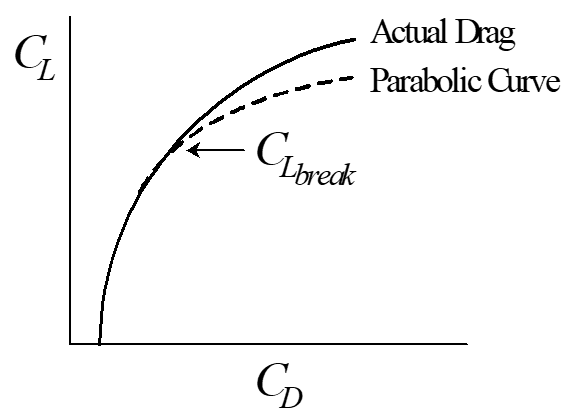

“Polar” form of simple drag polar:

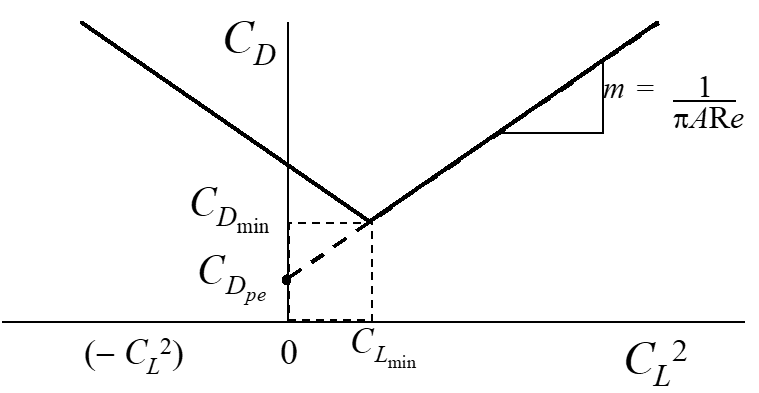

Linearized form of simple drag polar:

5.6.2 Complicating Factors

Airflow Separation Effects

Drag Polar Equation Accounting for Flow Separation:

\[C_D = C_{D_{\mathrm{min}}} + \frac{\left(C_L - C_{L_{\mathrm{min}}}\right)^2}{\pi \mathrm{AR} e} +k_2\left(C_L - C_{L_{\mathrm{break}}}\right)\]

- Delete last term if \(C_L < C_{L_{\mathrm{break}}}\)

- Determine \(k_2\) from flight test

Reynolds Number Effects

(refs 5.4, 5.11)

- Calculate length \(\mathrm{Re}_L\) and friction coefficient (\(c_f\)) for each surface as

\[\mathrm{Re}_L = \frac{\rho Vl}{\mu} = 7.101 \times10^6 \left[\frac{\delta}{\theta^2} \right]\left[\frac{T_K + 110}{398}\right] l \]

\(T_K = \text{Kelvin}\)

\(l = \text{total length, ft}\)

\[c_f = \left[\frac{1.328}{\sqrt{\mathrm{Re}_L}}\right] \left[1 + 0.1305 M^2 \right]^{-0.12} \text{ laminar}\] or \[c_f = \left[\frac{0.074}{\left(\mathrm{Re}_L\right)^2} - \frac{1700}{\mathrm{Re}_L} \right] \text{ transition}\] or \[c_f = 0.455\left[\log \mathrm{Re}_L\right]^{-258} \left[1 + 0.144 M^2\right]^{-0.65} \text{ turbulent}\]

- In general, \(c_f\) decreases as \(\mathrm{Rn}\) increases (unless transitioning from laminar to turbulent flow)

- Friction drag \(= c_f q S_{\mathrm{wet}}\) for each component (\(S_{\mathrm{wet}} = \text{wetted area}\))

- Correct from test day to standard day aircraft drag coefficient by summing differences of each component’s drag change

\[\Delta C_D = \frac{\sum\left(c_{f_s} - c_{f_t} \right) S_{\mathrm{wet}}}{S} \]

Wing Camber or Incidence Angle Effects

Note slight increase in drag as lift decreases towards zero

Linearized drag polar for aircraft with wing camber and/or incidence

Revised drag polar equation accounting for wing camber or incidence

\[C_D = C_{D_{\mathrm{min}}} + \frac{\left(C_L - C_{L_{\mathrm{min}}} \right)^2}{\pi \mathrm{AR} e} \]

- Generally not necessary since most flight occurs above \(C_{L_{\mathrm{min}}}\)

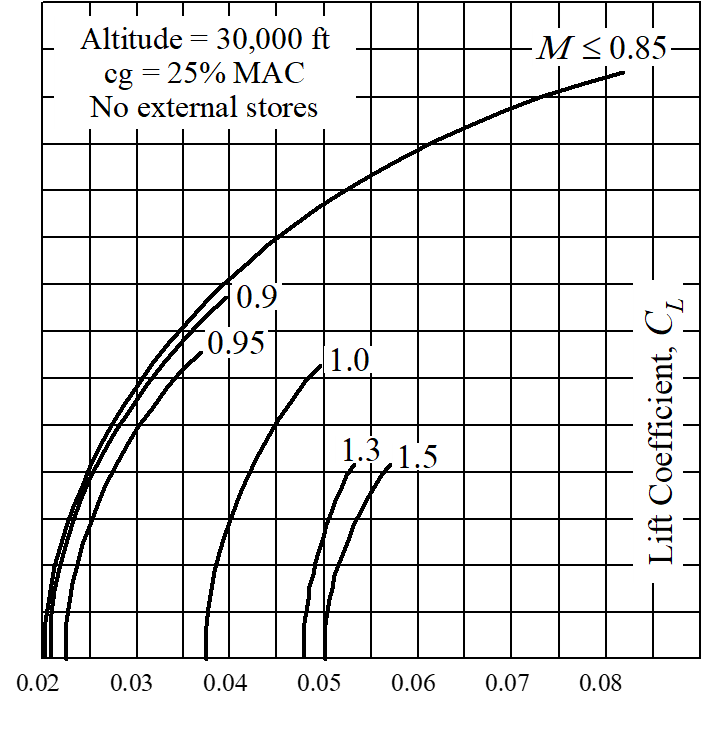

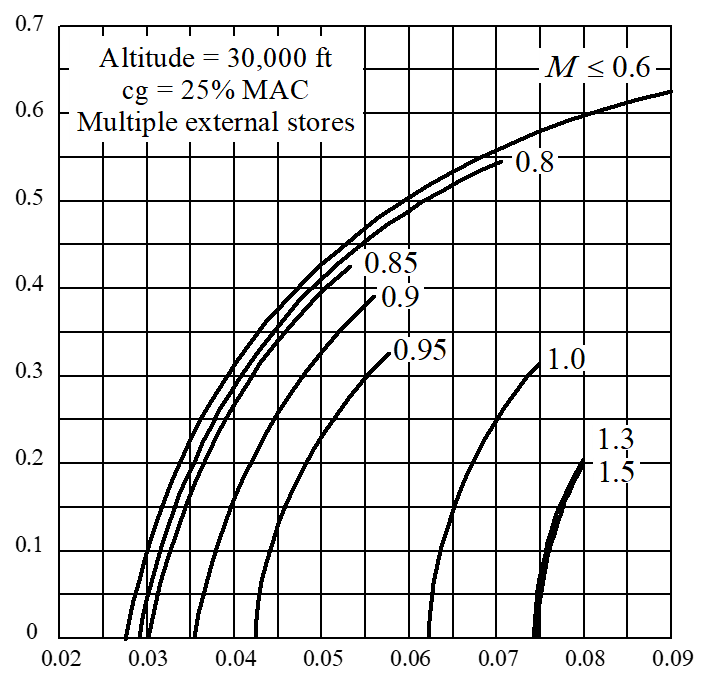

Mach Number Effects

- Aircraft with low parasitic drag coefficients and high fineness ratios pay a relatively small “wave drag” penalty.

- With external stores, same aircraft pays larger Mach penalty

Propeller Slipstream Effects

- a.k.a “scrubbing” drag

- Propwash increases flow speed over surface within slipstream

- More drag is created by higher \(q\) and vorticity.

- Function of prop speed and power absorbed (\(C_p\)) or thrust (\(C_T\))

- Problem should be addressed in airframe or propeller models

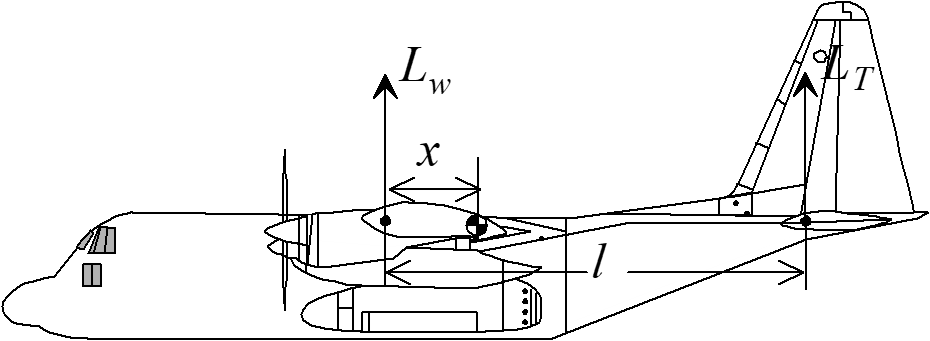

Trim Drag Effects

(ref 5.4)

\(e = \text{wing Oswald efficiency factor}\)

\(e_t = \text{tail Oswald efficiency factor}\)

\(b = \text{span}\)

\(b_t = \text{tail span}\)

\(x = \text{wing ac-to-cg distance}\)

\(l = \text{wing ac to tail ac distance}\)

\(S = \text{Area}\)

\[C_{D_{\mathrm{trim}}} = \frac{W^2}{\pi q^2 Sb^2e} \left[\frac{2}{lW}\left[x_0 - x_1\right] + \frac{1}{l^2} \left[1 + \frac{S}{S_t} \frac{e}{e_t} \left(\frac{b}{b_t}\right)^2\right] \left[x_0^2 - x_1^2\right] \right]\]

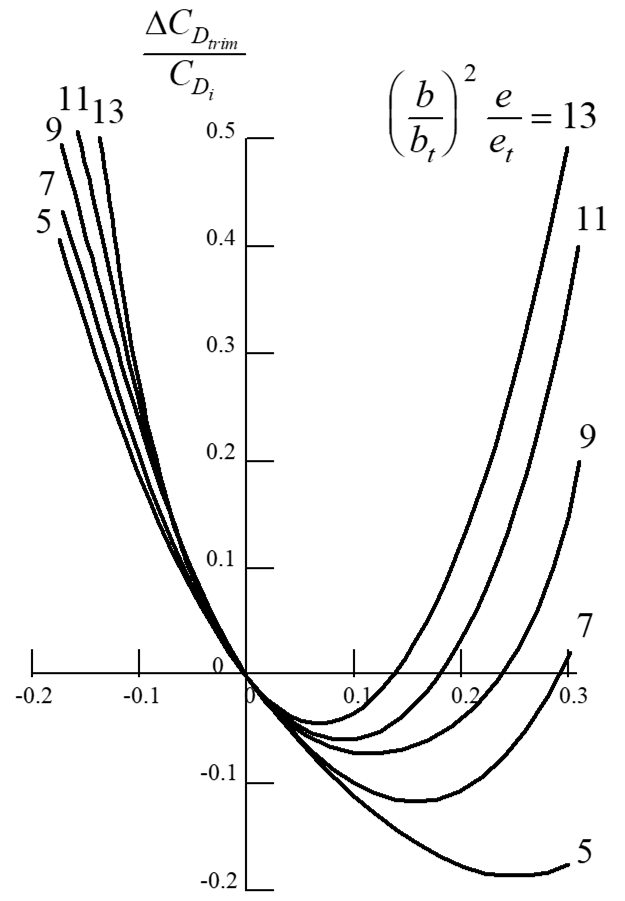

Trim drag change relative to total induced drag:

\[\frac{\Delta C_{D_{\mathrm{trim}}}}{\Delta C_{D_i}} = \frac{x}{l} \left[\frac{x}{l} \left(\frac{b}{b_t}\right)^2 \frac{e}{e_t} - 2 \right] \]

Plot of above equation

5.6.3 Drag Polar Analysis

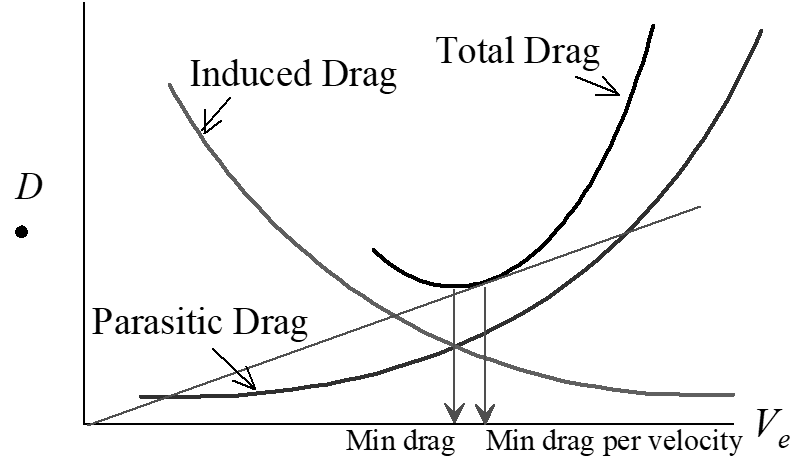

\[D = \bar{q}SC_D = \bar{q}S \left[C_{D_0} + \frac{C_L^2}{\pi \mathrm{AR} e} \right] = \frac{1}{2}\rho_0 V_e^2 S\left[C_{D_0} + \frac{W^2}{\pi \mathrm{AR} e \left(\frac{1}{2} \rho_0 V_e^2 S \right)^2} \right]\]

- For a given configuration (\(C_{D_0} \text{, } S \text{, } \mathrm{AR} \text{, } e\))

\[D = k_1 V_e^2 + k_2 \frac{W^2}{V_e^2} \]

first term = parasitic drag, second term = induced drag

- For any given weight, \(D = f(\text{equivalent airspeed})\) only

- Minimum total drag occurs when \(D_{\mathrm{induced}} = D_{\mathrm{parasitic}}\)

- same as speed where \(C_{D_i} = C_{D_0}\)

- occurs at max \(C_L/C_D\) ratio (same as max \(L/D\) ratio)

- Minimum drag/velocity occurs at min slope of Drag vs V curve

- same as speed where \(3C_{D_i} = C_{D_0}\)

- occurs at max \(C_L^{1/2}/C_D\) ratio

Power required = drag x true airspeed

\[P_{\mathrm{req}} = DV_T = D\frac{V_e}{\sqrt{\sigma}} = k_1\frac{V_e^3}{\sqrt{\sigma}} + k_2\frac{W^2}{\sqrt{\sigma}V_e} \]

Minimum total \(P_{\mathrm{req'd}}\) occurs when \(P_{\mathrm{induced}} = P_{\mathrm{parasitic}}\)

- same as speed where \(C_{D_i} = 3C_{D_0}\)

- occurs at max \(C_L^{3/2}/C_D\) ratio

Minimum power/velocity occurs at min slope of \(P_{\mathrm{req'd}}\) vs \(V\) curve

- same as speed where \(C_{D_i} = C_{D_0}\)

- occurs at max \(C_L /C_D\) ratio

Optimum Aerodynamic Flight Conditions

Gliders/ Engine-Out Flight

- Max range (minimum glide slope) occurs at max \(C_L/C_D\)

- same as condition where \(C_{D_0} = C_{D_i}\) if drag polar is parabolic

- Min sink rate (minimum power req’d) occurs at max \(C_L^{3/2} /C_D\) ratio same as condition where \(3C_{D_0} = C_{D_i}\) if drag polar is parabolic

Reciprocating Engine Aircraft (assuming constant \(\mathrm{BSFC}\) & prop \(\eta\))

- Max range (minimum power/velocity) occurs at max \(C_L/C_D\) ratio

- same as condition where \(C_{D_0} = C_{D_i}\) if drag polar is parabolic

- Max endurance (minimum power req’d) occurs at max \(C_L^{3/2} / C_D\)

- same as condition where \(3C_{D_0} = C_{D_i}\) if drag polar is parabolic

Turbine Jet Engine Aircraft (assuming constant \(\mathrm{TSFC}\))

- Max range at constant altitude (minimum drag/velocity)

- occurs at max \(C_L^{1/2} / C_D\) ratio

- same as condition where \(C_{D_0} = 3C_{D_i}\) if drag polar is parabolic

- Best cruise/climb range (maximum \(\left[M \times L/D \right]\) ratio)

- occurs at max \(C_L/C_D^{3/2}\) ratio

- same as condition where \(C_{D_0} = 2C_{D_i}\) if drag polar is parabolic

- Best endurance (minimum drag)

- occurs at max \(C_L/C_D\) ratio

- same as condition where \(C_{D_0} = C_{D_i}\) if drag polar is parabolic

To calculate optimum speed \(V_2\) for configuration2 & weight2 based on optimum speed \(V_1\) at configuration1 & weight1

5.7 References

| 5.1 | Roberts, Sean “Aerodynamics for Flight Testers” Chapter 3, Subsonic Aerodynamics, National Test Pilot School, Mojave, CA, 1999 |

| 5.2 | Lawless, Alan R., et al, “Aerodynamics for Flight Testers” Chapter 4, Drag Polars, National Test Pilot School, Mojave ,CA, 1999 |

| 5.3 | Hurt Hugh H., “Aerodynamics for Naval Aviators,” University of Southern California, Los Angeles, CA, 1959. |

| 5.4 | McCormick, Barnes W., “Aerodynamics, Aeronautics, and Flight Mechanics,” Wilet &Sons, 1979 |

| 5.5 | Stinton, Darryl, “The Design of the Aeroplane,” BSP Professional Books, Oxford, 1983 |

| 5.6 | Roskam, Jan Dr., “Airplane Design, Part VI,” Roskam Aviation and Engineering Corp. 1990 |

| 5.7 | Anon, “Equations, Tables, and Charts for Compressible Flow” NACA Report 1135, 1953 |

| 5.8 | Lewis, Gregory, “Aerodynamics for Flight Testers” Chapter 6, Supersonic Aerodynamics, National Test Pilot School, Mojave CA, 1999 |

| 5.9 | White, Frank M. “Fluid Mechanics” pg 29, McGraw-Hill, 1979, ISBN 0-07-069667-5. |

| 5.10 | Anderson, John D. Jr, “Introduction to Flight” pg 142, McGraw-Hill, 1989, ISBN 0-07-001641-0. |

| 5.11 | Twaites, Bryan, Editor, “Incompressible Aerodynamics: An Account of the steady flow of incompressible Fluid Past Aerofoils, Wings, and Other Bodies,” Dover Publications, 1960. |